Ama-screw air compressor e-OPPAIR PM VSD, njengemishini yokucindezela umoya esebenza kahle futhi ethembekile, asetshenziswa kabanzi emikhakheni eyahlukene yokukhiqiza izimboni. Ukuze kuhlangatshezwane nezidingo ezithile zokukhiqiza, ukulungiswa okufanele kwamapharamitha e-rotary air compressor kubalulekile. Lesi sihloko sizochaza ukuthi ungawalungisa kanjani amapharamitha omsebenzisi we-PM VSD screw air compressor ukuze akusize ukuthi usebenzise kangcono futhi ugcine i-compressor yakho.

I. Izimiso Eziyisisekelo ZesikulufuUmoyaAma-compressor

I-screw compressor ngokuyinhloko iqukethe ama-rotor amabili ahambisanayo, ahlanganisa ama-mesh abesilisa nabesifazane. I-rotor yesilisa iyi-rotor esebenzayo, kanti i-rotor yesilisa iyi-rotor engasebenzi. Iqhutshwa yimoto kagesi, i-rotor yesilisa ijikeleza i-rotor yesilisa, iqedela inqubo yokungenisa umoya nokucindezela. Lesi sakhiwo sinikeza izinzuzo zokusebenza kahle kakhulu, ukuthembeka okuhle kakhulu, kanye nekhono lokunikeza umfutho womoya ozinzile.

II. Ukubaluleka Kokulungiswa Kwepharamitha Yomsebenzisi

Amapharamitha omsebenzisi we-screw compressor afaka phakathi umfutho womoya, ukugeleza komoya, kanye nesivinini senjini. Ukulungisa la mapharamitha kuthinta ngqo ukusebenza kanye nokusebenza kahle kwe-compressor. Ukulungiswa kwamapharamitha okufanele kungathuthukisa ukusebenza kahle kwe-compressor, kunciphise ukusetshenziswa kwamandla, futhi kwandise impilo yemishini. Ngakho-ke, ukwazi kahle indlela efanele yokulungisa amapharamitha kubalulekile kubasebenzisi.

III. Izindlela Zokulungisa Amapharamitha Zama-Screw Air Compressor

Ukulungiswa kwepharamitha yama-screw air compressors kuncike kumodeli ethile yemishini kanye nokusetshenziswa kwayo. Ngokuvamile, kudingeka izinyathelo ezilandelayo:

1. Okokuqala, hlola i-air compressor. Hlola ukuthi lezi zingcindezi ezintathu zijwayelekile: ingcindezi yokungena, ingcindezi yokukhipha, kanye nengcindezi yokukhipha umoya. Hlola ukuthi izinga likawoyela lingaphakathi kwebanga elijwayelekile.

2. Ngemva kokuqinisekisa ukuthi umshini usebenza kahle, qala usethe bese ulungisa amapharamitha ebhokisi lokulawula. Nquma iphuzu lokucindezela ngokusekelwe ekusetshenzisweni komoya wangempela bese ulifaka ebhokisini lokulawula.

3. Lungisa ingcindezi elinganisiwe yomshini. Indlela ejwayelekile yokulungisa iwukuqala ngokunciphisa ingcindezi iye enanini elibekiwe (ngokuvamile elibekwe phakathi kwamabha angu-7.5 no-8), bese ukhulisa ingcindezi kancane kancane ukuze ubone izimo zokusebenza komshini.

4. Lungisa izinga lokushisa lokukhipha ugesi emshinini: Uma ugesi ushisa kakhulu, ungawehlisa izinga lokushisa lokukhipha ugesi ngokulungisa amapharamitha afana nokushisa komoya wokungena komshini, izinga lokugeleza kwamanzi okupholisa emshinini opholile, kanye nezinga lokugeleza kwamanzi okupholisa emshinini opholile.

IV. Izinyathelo Zokuqapha Ukulungiswa Kwepharamitha

- Ngaphambi kokulungisa amapharamitha, qiniseka ukuthi uyaziqonda izici zokusebenza kwemishini kanye nemininingwane yokusebenza ukuqinisekisa ukuphepha nokusebenza kahle kwenqubo yokulungisa.

- Ngesikhathi sokulungisa, qapha ngokucophelela isimo sokusebenza kwemishini kanye nezinguquko kumapharamitha ahlukahlukene, bese uxazulula ngokushesha noma yiziphi izinkinga.

- Ngemva kokuphothulwa kokulungiswa, bheka futhi uhlole imishini isikhathi esithile ukuqinisekisa ukuthi ukulungiswa kwepharamitha kufinyelele imiphumela ehlosiwe.

- Yenza ukulungiswa nokulungiswa njalo kwemishini ukuqinisekisa ukusebenza kwayo okuvamile kanye nokuphila kwayo kwenkonzo.

- Uma kwenzeka noma yikuphi ukungasebenzi kahle kwemishini noma ukungasebenzi kahle, yivale ngokushesha ukuze ihlolwe ukuze ugweme umonakalo owengeziwe.

- Ngesikhathi sokusebenza nokulungiswa, naka ukuhlanzeka kwemvelo futhi ugcine indawo yokusebenza ihlanzekile futhi iphephile.

- Landela imithetho, imithethonqubo, kanye nezindinganiso ezifanele ukuqinisekisa ukuthi ukuphepha kwemishini kanye nokusebenza kwayo endaweni ezungezile kuyahlangabezana nezimfuneko.

8. Kunconywa ukuthi ukulungiswa kwemishini ebalulekile kanye nemingcele ebalulekile kwenziwe ochwepheshe abangochwepheshe ukuqinisekisa ukuphepha nokuzinza.

V.Ama-screw air compressor ayimishini evamile yezimboni.

Amaphuzu alandelayo kufanele aqashelwe ngesikhathi sokusebenza:

1. Ungagcini izinto ezivuthayo noma eziqhumayo eduze kwemishini. Futhi, qiniseka ukuthi umoya ongenayo awuvalwanga ngesikhathi sokusebenza.

2. Amapayipi acindezelwe; ungawakhululi amapulagi noma amavalvu amapayipi, njengezicupho zomusi kanye namapayipi okudonsa amanzi.

3. Hlola njalo ukusetshenziswa kukawoyela wokugcoba. Uma izinga likawoyela liphansi futhi likhuphuka kancane kancane, vala umshini. Gcwalisa kabusha uwoyela uma umshini ungenawo umfutho.

4. Hlola njalo isicupho somusi esizenzakalelayo se-screw air compressor ukuze sisebenze kahle ukuvimbela umswakama ukuthi ungangeni ohlelweni.

5. Khipha amanzi emathangini kawoyela negesi masonto onke. Iyunithi kumele isebenze okungenani amahora ama-2 ngesonto.

6. Ngesikhathi sokuhlola okuvamile kokusebenza, qiniseka ukuthi uhlelo lokulawula ingcindezi kanye nohlelo lokulawula ukuxhumanisa lusebenza kahle. Ukusebenza komshini okungavamile kwandisa ukusetshenziswa kwamandla futhi, ezimweni ezimbi kakhulu, kungabangela ukusha kwenjini.

7. Uma kwenzeka imisindo noma ukudlidliza okungajwayelekile ngesikhathi sokusebenza, vala umshini ngokushesha ukuze uhlolwe.

8. Ingcindezi yokusebenza kwe-air compressor kumele ihambisane nengcindezi ekhonjiswe ku-nameplate ukuqinisekisa ukusebenza kahle nokunciphisa ukusetshenziswa kwamandla.

I-OPPAIR ifuna amanxusa omhlaba wonke, wamukelekile ukusithinta uma unemibuzo: WhatsApp: +86 14768192555

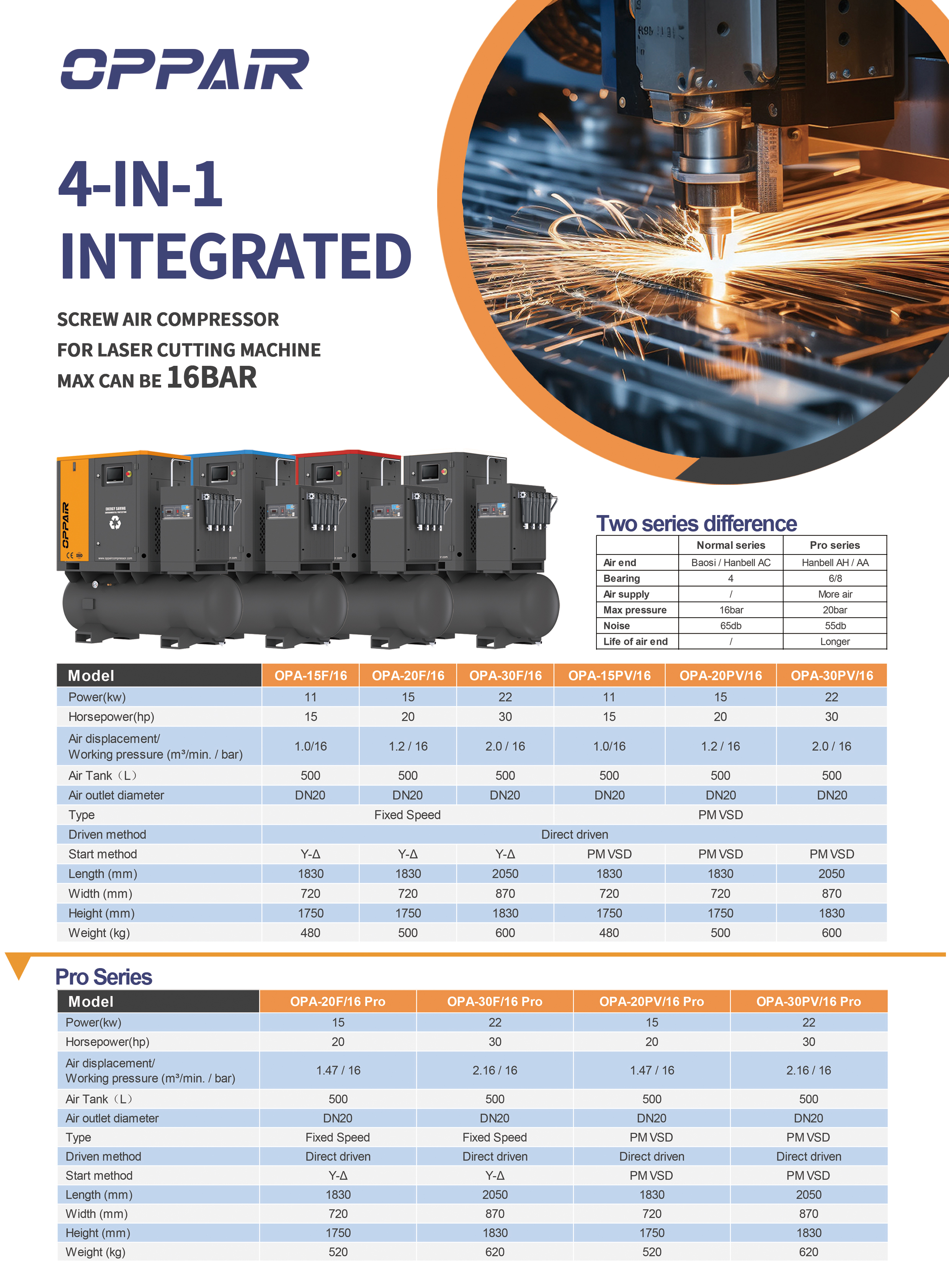

#PM VSD & Fixed Speed Screw Air Compressor #Ukusebenzisa i-laser cutting series 4-IN-1/5-IN-1/Skid mounted series#I-compressor yezigaba ezimbili #uchungechunge lwe-3-5bar low pressure#I-Compressor engenawo amafutha #I-Diesel Mobile Compressor #I-Nitrogen Generator #I-Booster

#Isicindezeli Somoya Esijikelezayo Sikagesi #Isicindezeli Somoya Esine-Air Dryer #Isikulufu Sokucindezela Komoya Esiphansi Esinomfutho Ophezulu#Ama-compressor omoya wonke akwisikulufo esisodwa#I-skid mounted laser cutting screw air compressor#isikulufa sokupholisa umoya se-oyili

Isikhathi sokuthunyelwe: Septhemba-28-2025