Kusehlobo, futhi ngalesi sikhathi, amaphutha okushisa aphezuluama-compressor omoyazivamile. Lesi sihloko sifingqa izimbangela ezahlukahlukene ezingaba khona zokushisa okuphezulu.

1. Uhlelo lwe-air compressor alunawoyela okwanele.

Izinga likawoyela lomgqomo kawoyela negesi lingahlolwa. Ngemva kokuvalwa nokukhululeka kwengcindezi, lapho uwoyela wokugcoba uphumula, izinga likawoyela kufanele libe phezulu kancane kunophawu oluphezulu lwamafutha (umugqa obomvu ngenhla). Ngesikhathi sokusebenza kwemishini, izinga likawoyela alikwazi ukuba ngaphansi kunophawu oluphansi lwamafutha (umugqa obomvu ngezansi). Uma kutholakala ukuthi inani likawoyela alanele noma izinga likawoyela alikwazi ukubonwa, misa umshini ngokushesha bese ugcwalisa uphethiloli.

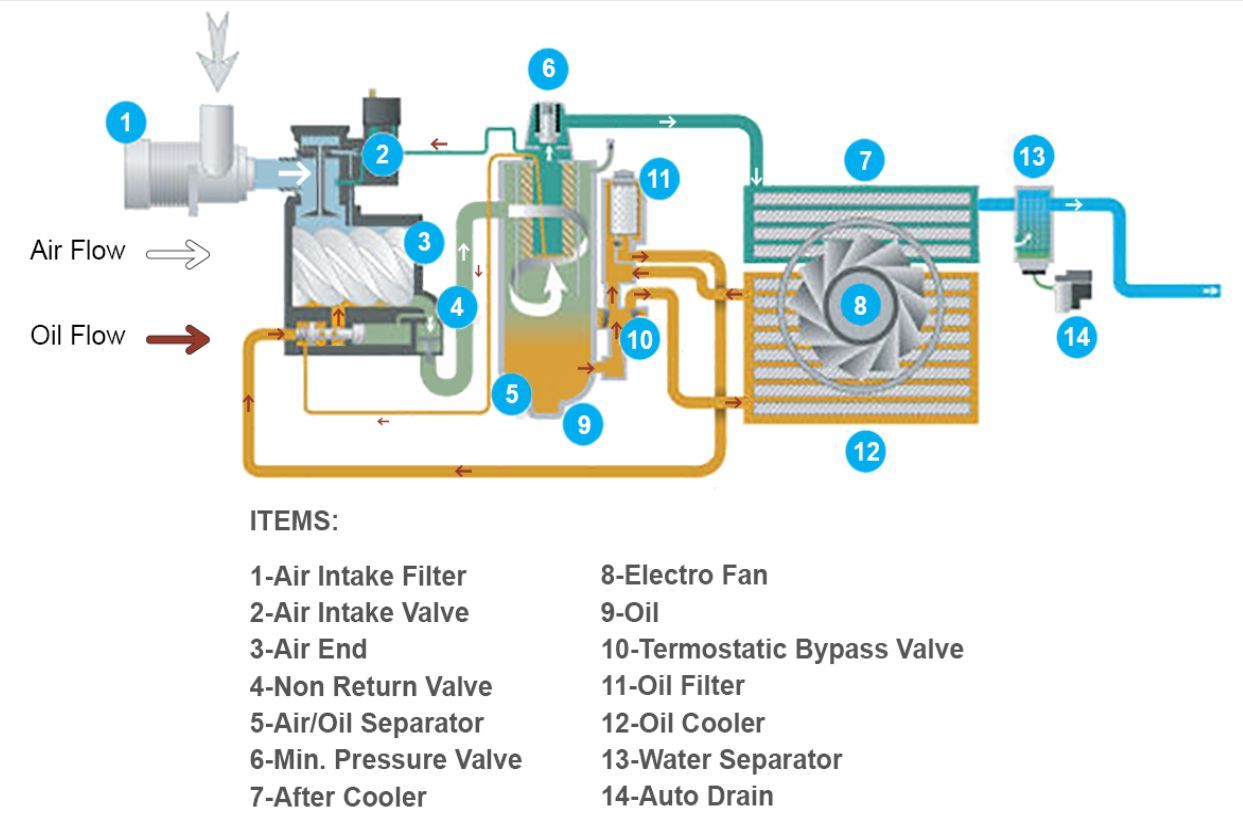

2. Ivalvu yokumisa uwoyela (ivalvu yokunquma uwoyela) ayisebenzi kahle.

I-valve yokumisa uwoyela ngokuvamile iyi-valve ye-solenoid enezikhundla ezimbili evame ukuvalwa, evulwa lapho iqala futhi ivalwa lapho ima, ukuze kuvinjelwe uwoyela osemgqonyeni kawoyela negesi ukuthi ungaqhubeki ufutha ungene ekhanda lomshini bese ufutha uphuma endaweni yokungena komoya lapho umshini umiswa. Uma ingxenye ingavulwanga ngesikhathi sokulayisha, injini eyinhloko izoshisa ngokushesha ngenxa yokuntuleka kwamafutha, futhi ezimweni ezimbi kakhulu, i-screw assembly izoshiswa.

3. Inkinga yesihlungi samafutha.

A: Uma isihlungi samafutha sivalekile futhi i-valve ye-bypass ingavulwa,isicindezeli somoyauwoyela awukwazi ukufinyelela ekhanda lomshini, futhi injini eyinhloko izoshisa ngokushesha ngenxa yokuntuleka kwamafutha.

B: Isihlungi samafutha siyavaleka futhi izinga lokugeleza liyancipha. Kukhona isimo lapho i-air compressor ingasuswa ngokuphelele ukushisa, futhi izinga lokushisa le-air compressor likhuphuka kancane ukuze kwakheke izinga lokushisa eliphezulu. Esinye isimo izinga lokushisa eliphezulu le-air compressor ngemva kokuba i-air compressor isusiwe, ngoba ingcindezi yangaphakathi kawoyela ye-air compressor iphezulu lapho i-air compressor ilayishiwe, uwoyela we-air compressor ungadlula, futhi ingcindezi kawoyela we-air compressor iphansi ngemva kokuba i-air compressor isusiwe. Isihlungi samafutha se-air compressor sinzima, futhi izinga lokugeleza lincane kakhulu, okubangela izinga lokushisa eliphezulu le-air compressor.

4. Ivalvu yokulawula ukushisa (ivalvu yokulawula izinga lokushisa) ayisebenzi kahle.

I-valve yokulawula ukushisa ifakwe phambi kwe-oyili cooler, futhi umsebenzi wayo ukugcina izinga lokushisa lokukhipha umoya lekhanda lomshini lingaphezu kwephuzu lokucindezela.

Umgomo wayo osebenzayo ukuthi ngenxa yokushisa okuphansi kukawoyela lapho uqala, isekethe yegatsha le-valve yokulawula ukushisa iyavulwa, isekethe eyinhloko iyavalwa, bese uwoyela wokugcoba ufafazwa ngqo ekhanda lomshini ngaphandle kwe-cooler; lapho izinga lokushisa likhuphuka ngaphezu kuka-40°C, i-valve yokulawula ukushisa ivalwa kancane kancane, Uwoyela ugeleza nge-cooler kanye negatsha ngesikhathi esifanayo; lapho izinga lokushisa likhuphuka ngaphezu kuka-80°C, i-valve ivalwa ngokuphelele, bese wonke uwoyela wokugcoba udlula nge-cooler bese ungena ekhanda lomshini ukuze upholise uwoyela wokugcoba ngezinga elikhulu.

Uma i-valve yokulawula ukushisa yehluleka, uwoyela wokugcoba ungangena ngqo ekhanda lomshini ngaphandle kokudlula efrijini, ukuze izinga lokushisa likawoyela linganciphi, okuholela ekushiseni ngokweqile.

Isizathu esiyinhloko sokwehluleka kwayo ukuthi i-coefficient of elasticity yeziphethu ezimbili ezizwela ukushisa ku-spool iyashintsha ngemva kokukhathala, futhi ayikwazi ukusebenza ngokujwayelekile ngokushintsha kwezinga lokushisa; okwesibili ukuthi umzimba we-valve ugqokile, i-spool ibambekile noma isenzo asisekho endaweni futhi asikwazi ukuvalwa ngokujwayelekile. Ingalungiswa noma ishintshwe ngokufanele.

5. Umlawuli wevolumu kaphethiloli akajwayelekile, futhi ivolumu yokufaka uphethiloli ingandiswa ngokufanele uma kudingeka.

Umthamo wokufakwa kukaphethiloli ulungisiwe lapho imishini iphuma efektri, futhi akufanele ishintshwe ngaphansi kwezimo ezijwayelekile. Lesi simo kufanele sibangelwe yizinkinga zomklamo.

6. Uma uwoyela wenjini udlula isikhathi sesevisi, uwoyela wenjini uzowohloka.

Ukugeleza kukawoyela wenjini kuba kubi, futhi ukusebenza kokushintshana kokushisa kwehla. Ngenxa yalokho, ukushisa okuvela ekhanda le-isicindezeli somoyaayikwazi ukususwa ngokuphelele, okuholela ekushiseni okuphezulu kwe-air compressor.

7. Hlola ukuthi isiqandisi samafutha sisebenza kahle yini.

Kumamodeli apholiswe ngamanzi, ungahlola umehluko wokushisa phakathi kwamapayipi okungena nawokuphuma. Ngaphansi kwezimo ezivamile, kufanele kube ngu-5-8°C. Uma kungaphansi kuka-5°C, kungase kube nokukhula noma ukuvaleka, okuzothinta ukusebenza kahle kokushintshana kokushisa kwe-cooler futhi kubangele ukushabalaliswa kokushisa. Njengoba inephutha, ngalesi sikhathi, i-heat exchanger ingasuswa futhi ihlanzwe.

8. Hlola ukuthi izinga lokushisa lokungena kwamanzi okupholisa liphezulu kakhulu yini, ukuthi ingcindezi yamanzi kanye nokugeleza kwawo kujwayelekile yini, bese uhlola ukuthi izinga lokushisa elizungezile liphezulu kakhulu yini kumodeli epholile emoyeni.

Izinga lokushisa lokungena kwamanzi okupholisa ngokuvamile akufanele lidlule ama-35°C, futhi izinga lokugeleza akufanele libe ngaphansi kwama-90% wezinga lokugeleza elibekiwe lapho ingcindezi yamanzi iphakathi kuka-0.3 no-0.5MPA.

Izinga lokushisa elizungezile akufanele libe ngaphezu kuka-40°C. Uma izidingo ezingenhla zingahlangatshezwa, zingaxazululwa ngokufaka imibhoshongo yokupholisa, ukuthuthukisa umoya ophuma endlini, nokwandisa isikhala segumbi lomshini. Ungahlola futhi ukuthi ifeni yokupholisa isebenza kahle yini, futhi uma kukhona ukwehluleka, kufanele ilungiswe noma ishintshwe.

Isikhathi sokuthunyelwe: Juni-02-2023