I-valve yokungenisa iyingxenye ebalulekile yesistimu ye-screw air compressor. Kodwa-ke, uma i-valve yokungenisa isetshenziswa ku-compressor yomoya eguquguqukayo yemagnethi ehlala njalo, kungase kube nokudlidliza kwe-valve yokungenisa. Uma injini isebenza ngesivinini esiphansi kakhulu, ipuleti lokuhlola lizodlidliza, okuholela emsindweni wokungenisa. Ngakho-ke, siyini isizathu sokudlidliza kwe-valve yokungenisa ye-compressor yomoya eguquguqukayo yemagnethi ehlala njalo?

Izizathu zokudlidliza kwevalvu yokungenisa ye-compressor yomoya eguquguqukayo ye-magnet ehlala njalo:

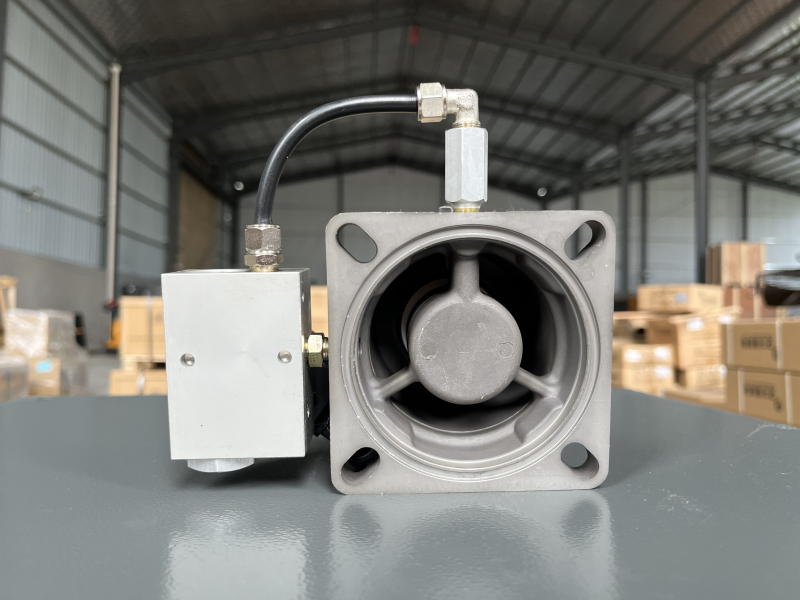

Isizathu esiyinhloko salesi simo yintwasahlobo ngaphansi kwepuleti levalvu yevalvu yokungenisa. Uma umthamo womoya wokungenisa umkhathi umncane, ukugeleza komoya akuzinzile futhi amandla entwasahlobo makhulu kakhulu, okuzobangela ukuthi ipuleti levalvu lidlidlize. Ngemva kokushintsha intwasahlobo, amandla entwasahlobo aba mancane, okungaxazulula izinkinga ezingenhla.

Ngokuyisisekelo, lapho i-input valve isebenza, i-input valve ye-air compressor iyavalwa, bese injini iqhuba injini enkulu ukuthi ingasebenzi. Uma i-valve ilayishiwe, i-input valve iyavuleka. Ngokuvamile, ipayipi legesi elikhulu kuno-5mm likhishwa embozweni ophezulu we-oil-gas separator, bese i-input valve ilawulwa yi-switch ye-solenoid valve (ngokuvamile i-solenoid valve iyavulwa). Lapho i-solenoid valve inikwa amandla, i-input valve engenawo umoya ocindezelweyo iphefumulelwa ngokuzenzakalelayo futhi ivulwe, i-input valve iyalayishwa, bese i-air compressor iqala ukufutha. Lapho i-solenoid valve incishisiwe amandla, umoya ocindezelweyo ungena ku-input valve, umfutho womoya uphakamisa i-piston, i-input valve iyavalwa, bese i-exhaust valve iyavuleka.

Umfutho womoya uhlukaniswe ngezindlela ezimbili, enye indlela ingena ku-valve yokukhipha umoya kanti enye indlela ingena ku-compressor. I-valve yokukhipha umoya inomshini wokulungisa usayizi wokukhipha umoya ukuze ilawule umfutho osemgqonyeni wokuhlukanisa. Umfutho ngokuvamile ungalungiswa ube ngu-3 kg, umfutho uyanda ngokujika ngokwewashi, kanti umfutho uyancipha ngokwewashi, bese kuthi i-nut elungisiwe ilungiswe.

Indlela yokulungisa ivolumu yomoya we-valve yokulayisha, lapho ukusetshenziswa kwegesi yemvelo yomsebenzisi kungaphansi kwevolumu yokukhipha elinganisiwe yeyunithi, ingcindezi ohlelweni lwenethiwekhi yamapayipi lomsebenzisi izokhuphuka. Lapho ingcindezi ifinyelela inani elibekiwe lengcindezi yokukhipha, i-valve ye-solenoid iyacinywa, umthombo womoya uyanqanyulwa, bese isilawuli singena ku-valve ehlanganisiwe yesilawuli sokungenisa. I-piston iyavalwa ngaphansi kwamandla entwasahlobo bese i-valve yokukhipha ivuleka. Umoya ocindezelwe ku-oyela-gas separator ubuyela endaweni yokungena yomoya, bese ingcindezi yehla iye enanini elithile.

Ngalesi sikhathi, ivalvu encane yokucindezela ivaliwe, inethiwekhi yepayipi yomsebenzisi ihlukaniswe neyunithi, futhi iyunithi isesimweni sokusebenza okungalayishwa. Njengoba ingcindezi yenethiwekhi yepayipi yomsebenzisi yehla kancane kancane iye enanini elibekiwe lokucindezela komthwalo, ivalvu ye-solenoid ithola amandla futhi ixhunywe emthonjeni womoya wokulawula wevalvu ehlanganisiwe kusilawuli sokungenisa. Ngaphansi kwesenzo sale ngcindezi, i-piston ivuleka ngokumelene namandla entwasahlobo, ngesikhathi esifanayo ivalvu yokukhipha umoya ivala, futhi iyunithi iqala kabusha ukusebenza kokulayisha.

Lokhu okungenhla kuyimbangela yokudlidliza kwevalvu yokungenisa ye-compressor yomoya eguquguqukayo yemagnethi ehlala njalo. Ivalvu yokungenisa isebenza ngokubambisana nevalvu yesolenoid, inzwa yokucindezela, kanye nesilawuli se-microcomputer ukulawula ukushintsha kwe-port yokungenisa ye-compressor. Lapho iyunithi iqala, ivalvu yokungenisa ivaliwe, edlala indima yokulungiswa kwe-air intake throttling, ukuze i-compressor iqale lapho umthwalo ulula; lapho i-compressor yomoya isebenza lapho umthwalo ugcwele, ivalvu yokungenisa ivuliwe ngokugcwele; lapho i-air compressor isebenza ngaphandle komthwalo, ivalvu yokungenisa ivaliwe futhi uwoyela negesi kuhlukaniswe. Ukucindezela ku-separator kukhishwa ku-0.25-0.3MPa ukuqinisekisa ukucindezela kokunikezwa kukawoyela kwenjini eyinhloko; lapho umshini uvaliwe, ivalvu yokungenisa ivaliwe ukuvimbela igesi ku-oil-gas separator ukuthi igeleze emuva, okubangela ukuthi i-rotor ibuyele emuva futhi kwenzeke ukujova kukawoyela e-port yokungenisa.

Isikhathi sokuthunyelwe: Agasti-01-2023